EasyDig History - Eggs are Strong

Fact: A circle is the strongest shape. Due to the even distribution of force; it can withstand much more pressure to its exterior than a square. There is no one point on a circle that receives more pressure than the other.

Around 10 years ago a rough piece of metal became the first concept of EasyDig shoring. Heavy and unwieldy it really wasn’t pretty; but it was functional.

Wayne and Kirby were owners back then, at Steinbach Hydrovac; a hydrovac company in South-eastern Manitoba. They were often requested to hydrovac Sewer and Water Main breaks.

As anyone familiar with water main breaks knows this is a messy and muddy situation at best of times. Especially in Canada, utilities are deep and to safely perform the repair a shoring system is needed. The big square shoring trench shields used together with an excavator totally destroy your lawn as well as your neighbour’s.

Wayne being the inventor that he is figured there must be a better solution. Taking the egg concept and the fact that they are stronger than any square box out there, he figured a circular shoring device would be the solution.

Wayne built the first circular shoring with the help of a local machining shop. With his welding experience it didn’t take much to put together a concept shoring. It was created in circular pieces that stacked together. Pieces could be added as the shoring was vacced into the ground.

This concept shoring immediately went to work with Micky Mouse; Steinbach Hydrovac’s small single axle hydrovac. Contractors loved the fact they need only call in a hydrovac instead of multiple pieces of equipment.

Homeowners loved that their lawns were not messed up with a big backhoe. Instead, a neat little hole was dug with a hydrovac and the circular shoring was sunk in to fix the water main break.

One draw back that this initial shoring design had was the fact it was still a heavy shoring device, similar to the square trench cages. Sure, it was neat and tidy and small, but it still was heavy and awkward to transport a large circle of heavy metal.

The shoring was used several times a month for the next few years. People loved it. Sewer and water contractors rented it. Everyone thought it was great. Little did they know it could become greater.

Kirby was determined to make something of this circular shoring, as he saw it as being unique to the industry. He thought about it for several years and then when life threw some unexpected curves at him, he decided to go all in and figure out a way to make this shoring concept a saleable product.

A patent officer was hired to certify the circular shoring as a patented product, since there was nothing like it in the industry.

An engineer was hired. The idea surfaced to try using aluminum, since a circle is very strong, unlike a square trench shoring box. So, the shoring was pressure tested at the engineer and aluminum passed the tests!

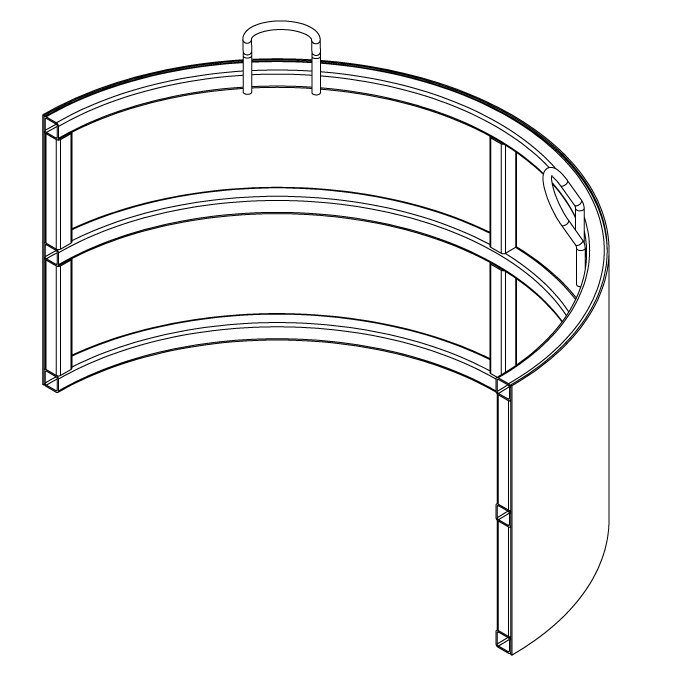

Much thought later the idea surfaced to cut the shoring in half to make 2 half circles. This idea won and the first concept of the half circle shoring was made. It surpassed Kirby’s expectation on pressure testing.

The new design was an aluminum shoring product. The circular design made it very strong. So strong that the engineer approved it up to 28’ deep in standard soil conditions.

Trial and error began on the first concept of the new half circle shoring design. This was a much improved version from the first concept, but still a work in progress.

Once happy with the new design the shoring was sent to a manufacturer and 10 sets were made as a trial run; to see if the product was something construction companies were interested in buying.

They sold in less than a year to hydrovac companies, cities and municipalities. Thus, EasyDig Shoring by EasyTech Infrastructure Group was born.

Today find our product across North America. This is only the beginning. Our aim is to become a global supplier of shoring. This is our first idea. There is more to come.